Description

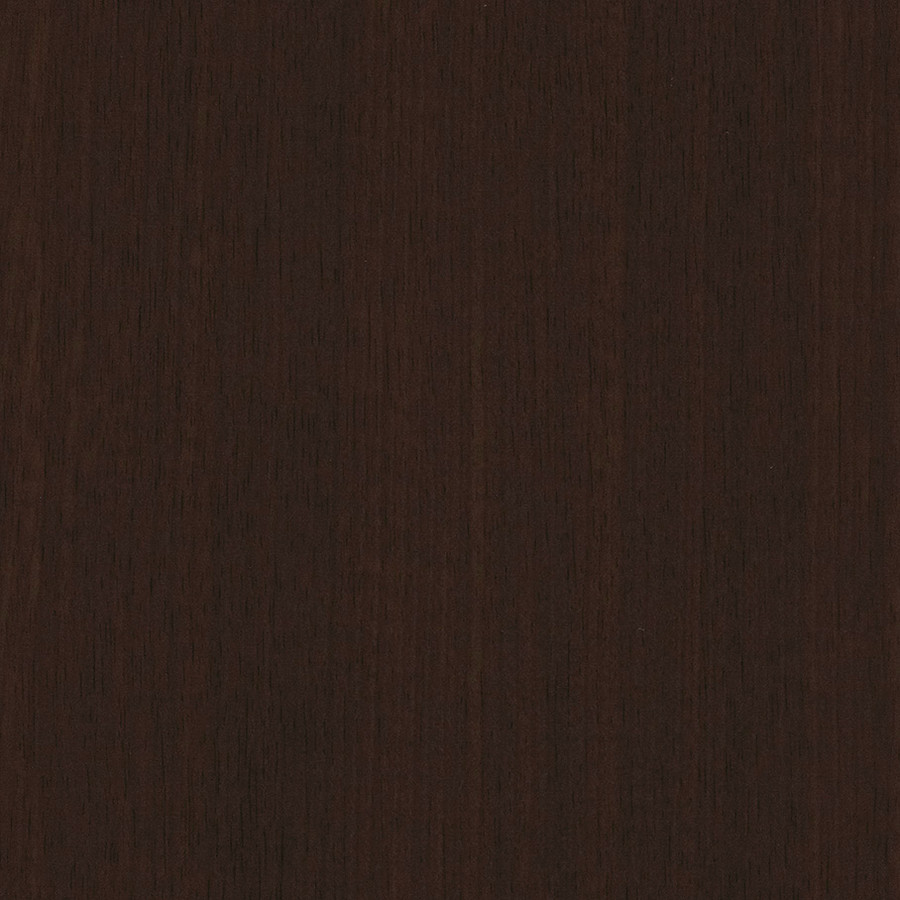

3M™ DI-NOC™ Architectural Finishes PO Polyolefin Film DW-2213PO

- 3M ID 7100329306

3M Diynock Film

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Technical Data Sheet

Revision I, March 2024

3M™ DI-NOC™ Architectural Finishes

NOTE: 3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin Film was formerly known as 3M™ DI-NOC™ Architectural

Finishes E-Series. The technical information and product composition has not changed, only the name.

Product Description

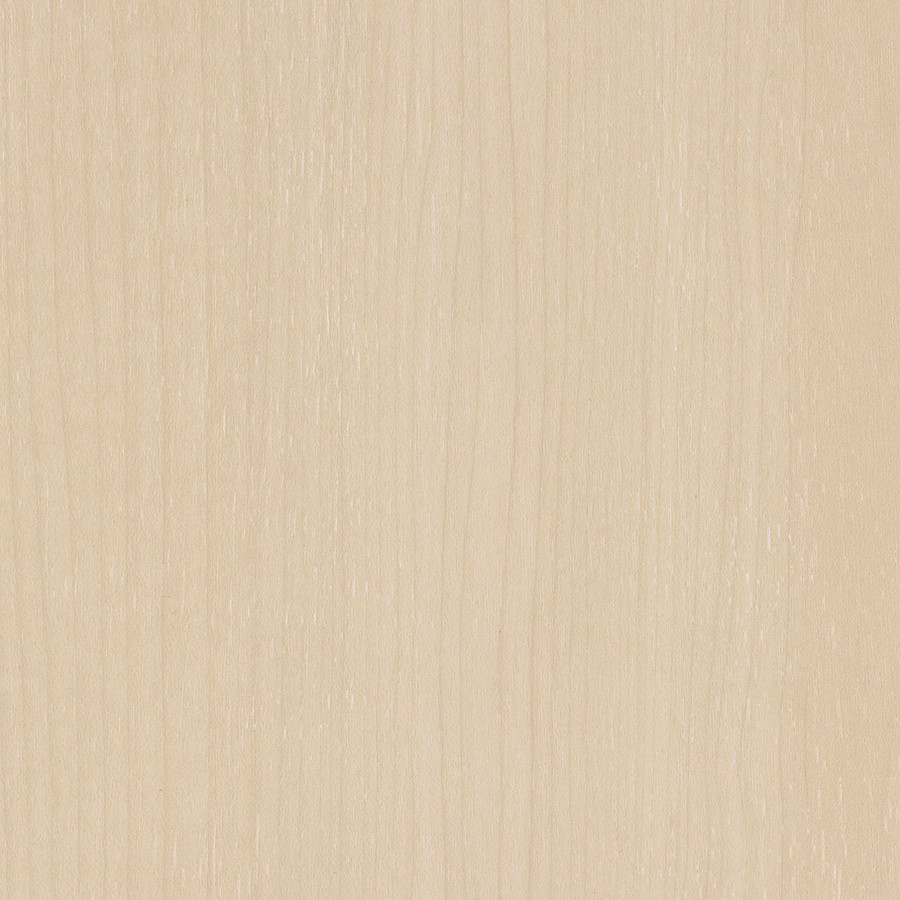

3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin Film (the “Product”) is a line of decorative surface finishes made with

polyolefin films that offer customers more choices as they pursue their sustainability goals. The Product is made with approximately 99.5%

non-PVC (non-vinyl) materials. These finishes are available in various patterns, colors, and textures including wood, ceramic, concrete, and

stone. The Products have a liner made from 40% recycled pulp as a base paper and printed with ink containing 10% biomass derived material.

Visit 3M.com/sustainability for more information on 3M’s commitment to sustainability.

Featured Benefits of 3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin Film

• Applications — Ideal for casework, doors, columns, walls, and more.

• Application Surfaces — Can be applied to metal, wood, interior glass, and more.

• Aesthetics — Designs resemble many types of surfaces to deliver the desired look.

• Remodel and Reuse — Shortens refurbishment downtime and brings entirely new designs to existing fixtures.

• Easy Application — 3M™ Comply™ Adhesive technology virtually eliminates air bubbles, simplifying and speeding application.

(See Figure 1).

• Expected performance life of eight years for interior vertical applications.

i IMPORTANT NOTE

3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin Film is NOT intended for applications with compound curves,

though applications with simple curves and around straight edges are possible. Consider other 3M™ DI-NOC™ Architectural

Finishes if applicability to compound curves is required. Refer to the 3M™ DI-NOC™ Architectural Finishes Installation Guide for

additional information.

Product Characteristics

The values in this table are typical, and are based on test data deemed reliable, but they are NOT warranted.

* Printing inks contain a polyvinyl chloride component.

Characteristic Value

Material

Film Polyolefin*

Adhesive Pressure-sensitive acrylic, permanent

Release Liner Silicone-coated polypaper

Thickness

Film +

Adhesive

7 mils (180 microns), not including the release liner.

Some designs vary slightly in thickness due to embossing.

Release Liner 6.2 mils (157 microns)

Maximum Roll Size 48 in. by 164 ft. (1,220 mm by 50 m) roll

Maximum Weight 55 lbs (25 kg) (approx.) for a 164 ft. (50 m) roll

Figure 1. 3M™ Comply™ Air Release Channels

2 Technical Data Sheet – Revision I, March 2024

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Product Line

The following 3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin Film designs are available by special order. Contact your local

sales representative or the 3M Help Center at 1-888-364-3577 for assistance.

* Only the pattern is available; does not include MT matte surface. DI-NOC E-Series E-Series PO Polyolefin Film and Standard DI-NOC have similar appearances but are not

identical.

Product Performance

The values in this table are typical, and are based on test data deemed reliable, but they are NOT warranted.

* Film applied to an aluminum plate

Ceramic/Concrete/Stone Wood

AE-1717PO CN-1621PO DW-1875PO* DW-2215PO* FW-1129PO FW-1296PO WG-1140PO

AE-1719PO CN-1958PO DW-1876PO* DW-2216PO* FW-1130HPO FW-1302PO WG-1141PO

AE-1930PO* CN-2112PO DW-1877PO* DW-2217PO* FW-1138PO FW-1306PO WG-1143PO

AE-1959PO* FA-1530PO DW-1878PO* DW-2218PO* FW-1211PO FW-1755PO WG-1710PO

AE-2152PO* FA-1531PO DW-1882PO* DW-2219PO* FW-1255PO FW-1770PO WG-2073PO

AE-2153PO* FA-2544PO DW-1889PO* DW-2222PO* FW-1256PO FW-1801PO WG-2450PO

AE-2162PO* ST-2171PO* DW-1891PO* DW-2223PO* FW-1257PO FW-1976PO WG-2451PO

AE-2163PO* ST-2533PO* DW-2197PO* DW-2229PO* FW-1261PO FW-1977PO WG-2452PO

AE-2165PO* ST-2534PO* DW-2202PO* DW-2473PO* FW-1262PO FW-1988PO WG-2453PO

AE-2508PO ST-2537PO* DW-2207PO* DW-2474PO* FW-1272PO FW-2425PO WG-2454PO

ST-2540PO* DW-2208PO* DW-2475PO* FW-1273PO FW-2426PO WG-2460PO

DW-2209PO* DW-2476PO* FW-1293PO FW-2427PO WG-2461PO

DW-2211PO* DW-2477PO* FW-1294PO WG-2462PO

DW-2212PO* DW-2479PO* WG-2463PO

DW-2213PO* WG-2464PO

Characteristic Evaluation Results

Dimensional

Stability*

4 in. by 4 in. (100 mm by 100 mm) crosscut in film after two days

at room temperature

Largest gap:

less than 0.06 in. (1.5mm)

Heat

Resistance* Aged at 150°F (66°C) for 28 days No delamination or visible

change

Thermal Cycle

Resistance* Cycled between -22°F and 150°F (-30°C and 66°C) for 14 days No delamination or visible

change

Moisture

Resistance* Aged at 104°F (40°C) and 95% humidity for 28 days No delamination or visible

change

Ultraviolet Light

Exposure Exposed to carbon arc accelerated weathering for 250 hours No visible change

Abrasion

Resistance

Taber® CS-17 Abrasion wheel: 1 kg (2.2 lbs) loading weight,

4,000 cycles

No wear-through surface

finish

Fire Resistance When used in interior applications as defined by NFPA 101

“Life Safety Code”, Test Method ASTM E84 Class A

VOC Emission

Testing CA Specification 01350 tested per CDPH Standard Method v1.2. Compliant as low-emitting

Technical Data Sheet – Revision I, March 2024 3

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Stain Resistance

Contaminants were in contact with the film surface for 24 hours and then removed using water or mild detergent. Diluted isopropyl alcohol

may be used for more difficult stains. Results may vary.

Contaminant Results

Coffee Removed with water – No permanent stains

Tea Removed with water – No permanent stains

Cola Removed with water – No permanent stains

Milk Removed with water – No permanent stains

Red Wine Removed with water – No permanent stains

Ketchup Removed with water – No permanent stains

Soy Sauce Removed with water – No permanent stains

Cooking Oil Removed with water – No permanent stains

Vinegar Removed with water – No permanent stains

Water Removed with water – No permanent stains

Mustard Removed with water – No permanent stains

Betadine iodine Removed with water – No permanent stains

Salt Solution (1%) Removed with water – No permanent stains

Soap Solution (1%) Removed with water – No permanent stains

Ammonia Solution (10%) Removed with water – No permanent stains

Citrate Solution (10%) Removed with water – No permanent stains

Ethyl Alcohol (50%) Removed with water – No permanent stains

4 Technical Data Sheet – Revision I, March 2024

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Resistance to Solvents, Cleaners, and other Chemicals

Film was applied to an aluminum plate, left for 72 hours, then immersed in the following chemicals. For immersion testing, the sample was

immersed in the cleaner or disinfectant for up to 72 hours, then rinsed with water and allowed to dry. Other cleaners and disinfectants with

the same active ingredient are expected to perform similarly.

Classification Solvent Immersion

Time Result

Water Water 24 hours No visible change

Acid Chloride (10%) 24 hours No visible change

Hydrogen Peroxide 72 hours No visible change

Base (Alkali) Sodium Hydroxide (10%) 24 hours No visible change

Alcohol

Ethanol 24 hours No visible change

Isopropyl Alcohol 72 hours No visible change

Ester Ethyl Acetate 5 minutes Deterioration observed

Ketone Methyl Ethyl Ketone 5 minutes Deterioration observed

Acetone 72 hours Deterioration observed

Aromatic Toluene 5 minutes Deterioration observed

Cleaners,

Disinfectants &

other Chemicals

2-in-1 Carbona® cleaner 72 hours No visible change

Accel® TB Disinfecting wipes 72 hours No visible change

Guardsman® AFTA 72 hours No visible change

Asepticare™ TB+II 72 hours No visible change

Birex® Disinfectant 72 hours No visible change

Bleach-Rite® Disinfectant 72 hours No visible change

Caltech Precise® hospital cleaner 72 hours No visible change

CaviWipes™ 72 hours No visible change

CIDEX® OPA 72 hours No visible change

Citrace® Germicide 72 hours No visible change

Citrace® II Hospital Germicidal Deodorizing cleaner 72 hours No visible change

Clorox® Bleach – 50% bleach/50% water 72 hours No visible change

Clorox® Broad Spectrum Quaternary Disinfectant 72 hours No visible change

Clorox® germicidal bleach spray with bleach 72 hours No visible change

Discide® Ultra disinfectant spray 72 hours No visible change

Ecolab® TB disinfectant cleaner 72 hours No visible change

Envirocide® Disinfectant decontaminating cleaner 72 hours No visible change

Fade-A-Dyne® blood remover 72 hours No visible change

Fantastik® Spray Cleaner 72 hours No visible change

Formula 409® 72 hours No visible change

Harvard Chemical 625® Hospital Grade Neutral Disinfectant 72 hours No visible change

Healthlink Citriguard® II Hard Surface Cleaner 72 hours No visible change

Husky® 891 72 hours No visible change

K2R® 72 hours No visible change

Lysol® 72 hours No visible change

Microquant® Quanternary detergent disinfectant – Ecolab 72 hours No visible change

Misty® disinfectant & deodorant 72 hours No visible change

Technical Data Sheet – Revision I, March 2024 5

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Product Use

The user is solely responsible for evaluating and determining whether the Product is suitable and appropriate for any particular use or

manufacturing process in which it may be used.

Consider These Factors in Determining the Suitability of the Product

Understand the unique characteristics of the Product and consider them when determining whether the Product is suitable for a given use.

Refer to the 3M™ DI-NOC™ Architectural Finishes Installation Guide for additional information.

1. Substrate texture affects film adhesion and ease of application.

Unless the substrate is very smooth, its texture may be visible through the film.

Compounds used to smooth a textured substrate permanently change that substrate.

Product removal may damage the substrate or its finish.

2. Application surface conditions affect film adhesion.

Ensure the existing paint, surface finish, or wall covering has an excellent bond to the substrate area where film will be applied.

Repair, prime, and paint the substrate as needed.

An adhesion promoter may be required to increase film adhesion.

3. Human and environmental conditions to consider:

Temperature and humidity in recommended range

Direct exposure to UV light (sunlight)

Heating or cooling ducts in close proximity

Unsealed substrates in front of water sources

People or equipment that will be in contact with the film

4. The film may contain a splice. The splice location is marked with a tab along the film edge. The installer must determine the impact of

the splice and work around it to make the best use of the material layout.

Cleaners,

Disinfectants &

other Chemicals

Oxivir® TB – Diversey 72 hours No visible change

Oxivir® TB Wipes – Diversey 72 hours No visible change

Oxivir® TB ready to use wipes – Diversey 72 hours No visible change

QD-64® lemon Disinfectant – Quest 72 hours No visible change

3M™ Quat Disinfectant #5 72 hours No visible change

Quest 256® Neutral Disinfectant – Butchers 72 hours No visible change

Resolve® Spot & Stain cleaner 72 hours No visible change

SaniZide Plus® germicidal solution 72 hours No visible change

SaniZide Plus® germicidal wipes 72 hours No visible change

3M™ Sharpshooter™ 72 hours No visible change

Simply Green® 72 hours No visible change

Spartan® Clean by Peroxy® 72 hours No visible change

Spartan® Green Solutions® Neutral Disinfectant cleaner 72 hours No visible change

Spray Nine® 72 hours No visible change

Tide™ Powder Detergent 72 hours No visible change

TechniSat® TX1067 (70/30 IPA) 72 hours No visible change

Ivory® Ultra 72 hours No visible change

Virex® 256 cleaner 72 hours No visible change

Virox® 72 hours No visible change

Classification Solvent Immersion

Time Result

6 Technical Data Sheet – Revision I, March 2024

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Factors Affecting Performance Life

The actual performance life of the Product is affected by:

– Selection, condition, and preparation of the application surface

– Application surface texture

– Application technique

– Angle and direction of sun exposure

– Environmental conditions

– Cleaning or maintenance methods

Processing Options

Processing of the Product is strictly on a user test-and-approve basis. The user is responsible for results in all processing applications.

Printing

The Product is NOT designed for surface printing and films in the series have various surface textures. Printing is strictly on a user test-andapprove basis. No warranty is made for the quality or durability of printed Product.

Cutting

Electronic cutting, weeding, and use of application tape with the Product is strictly on a user test-and-approve basis. Users should consider

the following: (1) the Product’s liner is not intended for electronic cutting; (2) there is currently no recommended application tape that

properly adheres to the face of the Product to hold cut shapes in place.

Application and Removal Guidelines

The values in this table are typical, and are based on test data deemed reliable, but they are NOT warranted. See the 3M™ DI-NOC™

Architectural Finishes Installation Guide for additional information.

Characteristic Value

Application Surface Type Smooth, hard, non-porous (sealed) material

Application Location Interior

Application Temperature 54°F to 100°F (12°C to 38°C) air and application surface

Application Method Dry application

High Humidity

Environments

The Product is NOT recommended for interior applications

where condensation consistently occurs.

Product Removal Heat at 176°F to 212°F (80°C to 100°C)

Technical Data Sheet – Revision I, March 2024 7

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Adhesion Compatibility with Application Surfaces

The following table contains peel adhesion information for the film peeled from various surfaces. A number of surfaces provide acceptable

adhesion without the use of an adhesion promoter. Examples of increased adhesion with the use of adhesion promoters on certain surfaces

are presented. Surfaces vary widely, so adhesion should be individually assessed on each customer’s substrates. Some surfaces are porous

and must be sealed before application of DI-NOC™ to prevent outgassing of the surface over time.

The test specimens were applied to the substrate and conditioned at 68°F (20°C) for 48 hours, then peel tested at 180 degrees at a tensile

speed of 12 in./min (300 mm/min).

WP-2000 undiluted for testing

Acceptable adhesion

Adhesion failure

1 Bubbles may appear under film applied to a plastic substrate which was not fully cured before application due to outgassing.

2 3M highly recommends using an adhesion promoter anywhere DI-NOC™ film is wrapped and overlapped around edges, due to the additional stress that wrapping places on

the film.

3 Sealer was wiped with isopropyl alcohol to improve adhesion. Adhesion was tested using a spring scale per the 3M™ DI-NOC™ Architectural Finishes Installation Guide and

passed at 800-1000 g/in.

Shelf Life and Storage

Shelf Life

Apply the Product within two years of the date of purchase. The storage conditions specified in this document must be maintained in order

to preserve the full shelf life.

Storage Conditions

• 40°F to 90°F (4°C to 32°C)

• Away from direct sunlight and high humidity

• Clean, dry area

• Original container with end caps, in the plastic sleeve, stored horizontally, a maximum of six cartons high

• Bring the Product to room temperature before application

Substrate Application Surface

No Adhesion

Promoter

lbs/in. (N/25 mm)

Adhesion Promoter

WP-2000

(water-based)

lbs/in. (N/25 mm)

Primer 94 (solventbased)

lbs/in. (N/25 mm)

Wood MDF (w/ sealer) 2 (8)3 11 (51) 4 (18)

Painted MDF 4 (20) 12 (52) 7 (31)

Boards Gypsum Board (w/skim

coat & sealer) 2 (8)3 8 (35) 4 (19)

Metals

Aluminum 11 (47) 11 (48) 11 (47)

Anodized Aluminum 5 (23) 13 (56) 11 (49)

Stainless Steel 6 (26) 13 (56) 6 (28)

Glass Glass 6 (26) 13 (58) 6 (26)

Plastics1

ABS 6 (28) 13 (56) 10 (44)

Acrylic 5 (22) 12 (54) 10 (43)

Polyester (PETG) 7 (29) 11 (51) 10 (45)

Polypropylene 1 (2) 4 (17) 4 (20)

Polyethylene 1 (3) 5 (21) 1 (3)

Polycarbonate 6 (28) 12 (53) 10 (44)

DI-NOC™ Film 5 (24)2 11 (49) 9 (42)

8 Technical Data Sheet – Revision I, March 2024

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Cleaning and Maintenance

Regular cleaning helps maintain the appearance of the finish. Use mild detergent, water, and a soft cloth or sponge without abrasives. For

difficult stains, spot clean with a solution of 70% isopropyl alcohol (IPA) and 30% water and a soft cloth. Avoid using strong solvents or

detergents that are either highly alkaline (pH>11) or highly acidic (pH<3). Do NOT use ammonia, chlorine, strong organicbased cleaning

products, polishing or cleaning compounds, hard-bristle brushes, or electric polishing equipment. Use only clean, nickfree tools and wipe

gently.

Health and Safety

! CAUTION

When handling any chemical products, read the manufacturers’ container labels and the safety data sheets (SDS) for important

health, safety, and environmental information. To obtain SDS for 3M products go to 3M.com/SDS. To request SDS by mail, or in

case of an urgent situation, call 1-800-364-3577 or 1-651-737-6501.

When using any equipment, always follow the manufacturer’s instructions for safe operation.

! WARNING

To reduce the risks of personal injury and/or property damage associated with glass breakage:

A glass surface covered by a film with areas of high opacity or dark-colored ink will absorb more heat than other glass surfaces when

exposed to sunlight. Heat absorption can create thermal expansion that could result in glass breakage or cracking. Do NOT use a film

with areas of high opacity or dark-colored ink on glass surfaces with significant exposure to sunlight.

Problem Solution

Dust and Grit Wipe with a soft, damp cloth.

Soiled (but not gritty) Use water and a soft cloth.

Heavily Soiled Clean first using a solution of mild liquid detergent and

water, then use clear water. Wipe gently with a soft cloth.

Difficult Stains Spot clean with a solution of 70% IPA and 30% water.

Type of Surface

Damage Cause of Surface Damage Method to Reduce Visibility

Mar Dragging an item (such as a colored briefcase) across

the film, leaving a deposit of color on the surface. Rub with a soft cloth and warm soapy water to remove the mar.

Indentation Pressing into the film surface without breaking the surface, such as pressure from a chair.

Carefully heat the indentation with a heat gun, which allows the film surface to rebound and reduce the indentation’s visibility.

Scratch

Breaking the surface layer of film leaving a slightly jagged whitish mark on the surface, such as by dragging

a sharp rivet from a purse.

Rub with a surface restorer such as 3M™ Marine Vinyl Cleaner & Restorer

to reduce the visibility of scratches.

Gouge Breaking through the entire film, such as from a severe

impact from sharp chairs or carts.

Repair the film by cutting out the damaged film and replacing it with the

same pattern of film, or remove and replace the entire film panel.

Technical Data Sheet – Revision I, March 2024 9

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

LEEDv4 CREDITS

This section describes some of the options for acquiring LEED credits using 3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin

Film.

NOTE: Each application is different. It is the sole responsibility of the end user to evaluate and determine whether LEED credits can

be applied.

ID+C MR Credit, Interiors Life-Cycle Impact Reduction

– Option 1: Interior Reuse – The Product can be used to refinish salvaged, refurbished, or reused nonstructural materials.

– Option 2: Furniture Reuse – The Product can be used to refinish salvaged, refurbished, or reused furniture and furnishings.

ID+C, BD+C MR Credit, Construction and Demolition Waste Management

– Option 2: The Product can be used to refinish salvaged, refurbished, or reused interior materials, minimizing overall

construction waste.

ID+C, BD+C EQ Credit, Low-Emitting Materials

– The Product has been tested to and is in compliance with the General Emissions Evaluation (California Department of Public Health

[CDPH] Standard Method V1.2-2017).

BD+C MR Credit, Building Life-Cycle Impact Reduction

– Option 3: Building and Material Reuse – The Product can be used to refinish permanently installed interior elements (e.g. walls, doors).

BD+C MR Credit, Furniture and Medical Furnishings

– Option 3: Multi-attribute assessment of products – The Product can be used to refinish freestanding furniture and medical furnishings.

O+M MR Credit, Purchasing – Facility Maintenance and Renovation

– The Product can be used to refinish permanently installed interior elements (e.g. walls, doors)

– The Product has been tested to and is in compliance with the General Emissions Evaluation (CDPH Standard Method V1.2-2017)

BUILDING PRODUCT DISCLOSURE AND OPTIMIZATION INFORMATION

Environmental Product Declaration (EPD) or Life Cycle Analysis (LCA)

EPD and/or LCA information is not available.

Raw Material Source and Extraction Reporting

Raw material source and extraction information for this product is 3M confidential and is therefore not available.

Extended Producer Responsibility

A take-back or recycling program for this product is not available.

Bio-based Materials

The Product has not been tested to ASTM D6866.

Wood Products

The Product does not contain wood-based materials.

Materials Reuse

The Product can be used to refinish salvaged, refurbished, or reused materials and furniture.

Recycled Content

The Product does not contain pre- or post-consumer recycled content. The Product has a poly-coated paper release liner made from 40%

recycled pulp as a base paper.

10 Technical Data Sheet – Revision I, March 2024

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Optimized Manufacturing Process

The adhesive manufacturing Process for the Product has been optimized to use 20% less solvent than the previous adhesive manufacturing

process.

Material Ingredient Reporting

Product ingredient information for this product is 3M confidential and is therefore not available.

GreenScreen Benchmark or Cradle to Cradle Certification

Assessment or certification is not available on this product.

REACH Optimization

REACH Substance of Very High Concern certifications are on 3M.com/Regs (US) or 3M.com/SVHC (Europe).

Product Manufacture Supply Chain Optimization

Based on our analysis, 3M meets the required process and safety requirements as outlined in the criteria.

Location Valuation Factor

Based on supply chain, the Product does not meet location valuation factor requirements of being extracted, manufactured, and purchased

within 100 miles.

Phthalate Statement

The Product does not contain intentionally-added phthalate plasticizer.

PVC Statement

The Product is made with polyolefin films. The Product is made with approximately 99.5% non-PVC (non-vinyl) materials. The Product does

not contain more than 0.5% of a polyvinyl chloride-based component.

Technical Data Sheet – Revision I, March 2024 11

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Warranty Information

Product

3M™ DI-NOC™ Architectural Finishes E-Series PO Polyolefin Film (the “Product”) are decorative films for use on interior application

surfaces in commercial buildings.

Limited Warranty

1. For Products used in interior applications, 3M makes the following warranty (the “3M Limited Warranty”) for the applicable time period

stated below (“Warranty Period”), which will begin on the Product installation date.

2. The Product will have no significant discoloration, cracking, or other similar visual defects for the applicable time period below:

1 – Application of the Product to exterior application surfaces is NOT warranted.

3. For a buyer’s convenience, 3M may provide engineering or technical information, recommendations, installation instructions or guides,

and other information or materials relating to a Product (“Other Product Information”), but 3M makes only the 3M Limited Warranty,

and does not warrant any Other Product Information.

4. 3M has no obligation under the 3M Limited Warranty as to Product that has been: (a) modified, altered, or processed in any manner;

(b) stored, applied, installed, or used in a manner other than that 3M recommends in this document and in all Other Product Information;

(c) damaged through contact with a person or thing, misuse, accident, neglect, or other action by anyone other than 3M; (d) improperly

installed, including, without limitation, installation after the expiration of the Product’s shelf life or installation without proper surface

preparation; or (e) exposed to excessive heat, humidity, dirt, or UV light.

5. 3M must receive any 3M Warranty claim in writing no later than (a) the end of the Warranty Period; or (b) the discovery of the

3M Warranty claim, whichever is earlier.

Technical Information

Technical information, guidance, and other statements provided by 3M are based upon records, tests, or experience that 3M believes to be

reliable, but the accuracy, completeness, and representative nature of such information is not guaranteed. Such information is intended for

people with knowledge and technical skills sufficient to assess and apply their own informed judgment to the information. No license to any

intellectual property rights is granted or implied with respect to this technical information.

Product Selection and Use

Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product

in a particular application. Customer is solely responsible for evaluating the product and determining whether it is appropriate and suitable

for customer’s application, including conducting a workplace hazard assessment, reviewing all applicable regulations and standards, and

reviewing the product label and use instructions. Failure to properly evaluate, select, and use a 3M product in accordance with instructions

or to meet all applicable safety regulations may result in injury, sickness, death, and/or harm to property.

Application Warranty Period

Interior applications 5 years

Exterior application surfaces1 Use a 3M™ DI-NOC™ EX Series Product1

© 3M 2024. All rights reserved.

3M, DI-NOC, Comply, and Sharpshooter are trademarks of 3M.

Used under license in Canada.

All other trademarks are property of their respective owners.

Revision I, March 2024 Please recycle.

3M™ DI-NOC™ Architectural Finishes

E-Series PO Polyolefin Film

Commercial Branding and Transportation

3M Center, Building 223-3N-30

St. Paul, MN 55144

1-800-328-3908

3M.com/DI-NOC

Warranty, Limited Remedy, and Disclaimer

Unless a different warranty is specifically stated on the applicable 3M product packaging or product literature (in which case such warranty

governs), 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES

NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OR

CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ARISING OUT OF A COURSE OF DEALING,

CUSTOM, OR USAGE OF TRADE. If a 3M product does not conform to this warranty, the sole and exclusive remedy is, at 3M’s option,

replacement of the 3M product or refund of the purchase price.

Limitation of Liability

Except for the limited remedy stated above, and except to the extent prohibited by law, 3M will not be liable for any loss or damage arising

from or related to the 3M product, whether direct, indirect, special, incidental, or consequential (including, but not limited to, lost profits or

business opportunity), regardless of the legal or equitable theory asserted, including, but not limited to, warranty, contract, negligence, or

strict liability.

3M DI-NOC E-Series PO Polyolefin Film Tech Data Sheet

3M DI-NOC E-Series PO Polyolefin Film Tech Data Sheet